Menu

32/1000 roof sheeting can be laid either left to right or right to left. If you require the lay right to left simply turn the sheet around, making sure the overlapping edge is at the start of the process ready for the next sheet to overlap the underlapped side (as shown).

We recommend laying away from the common prevailing wind to help prevent wind whistling and water capillary. Please note the overlapping edge is always the unfinished castle overlapping the finished castle.

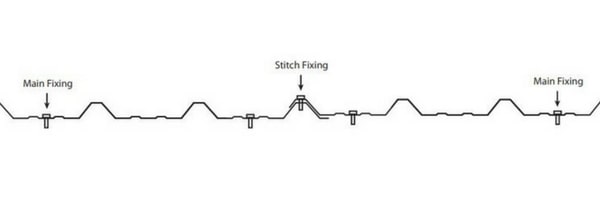

Fixing screws are highly recommended to screw between the strengthening ribs in the valley of the sheet (as shown). Usually fixed in the 1st, 3rd and 5th trough (left, middle, right) to have a symmetrical appearance and a strong holding into the purlins. Fixing in every purlin if possible but every two is adequate on short purlin spacings.

32/1000 roof sheeting (trapezoidal single skin) has 6 castles & 2 strengthening ribs in the troughs with a profile pitch of 200mm and profile depth of 32mm

We recommend using a maximum purlin spacing of 750mm for 0.5mm and 1250mm for 0.7mm, but not going any more than 1000mm for 0.5mm and 1500mm for 0.7mm unless it’s necessary.

Stitching the sheeting overlaps are very important (as shown). Stitching the overlapping castle every 500mm is adequate but if you can fix anything up to 750mm if necessary. This will help prevent water capillary seeping underneath the sheet. Also applying lap tape or silicone to the join will help decrease this even further.

If rooflights are being used, they operate in the same way as the steel sheeting. But clear silicone must be applied all the way around the sheet when being fitted to create a water tight seal. Some jobs that require building regulations will require you to use a Poppy Red Cap on the fixings to show where rooflights are situated when roofing maintenance is carried out. Also using the 29mm washer and 29mm cap with the main fixings will help prevent the fixing holes in the rooflights from leaking in due course.

Ridge and Barge flashings are always fitted after the sheeting. Again, using the stitching screw to fix through the flashing into the castle of the sheeting. Once this process is complete then fitting a foam infill between at the ridge end and the eaves end is recommended to help prevent birds / vermin entering the structure at the same time stopping wind pushing anything through during poor weather conditions.

Important Note

We do NOT recommend using foam infills if you have our Dripstop membrane system applied to your sheeting due to the roof requiring ventilation for the Dripstop to work at its optimum. Read More >

If the sheeting or flashings need cutting / trimming, we recommend using our Nibbler Attachment due to the clean precision cut it can offer. Angle grinders are commonly used but this will not offer a clean cut. A 110v Nibbler will be the most sufficient tool for this but our Nibbler Attachment Tool is handy if you only own a Drill.